Results of the project

Wayand

The whole story

Wayand – The Customer

For nearly 50 years, WAYAND has been a reliable partner to the automotive industry. Due to its extensive manufacturing expertise in plastic body parts, WAYAND is one of the leading specialists for exclusive small and medium-sized series in Europe..

WAYAND has been manufacturing exterior and interior plastic components for the automotive industry as well as for companies in the agricultural and commercial vehicle sector for decades as a flexible, medium-sized company. Intelligent plastic solutions for energy and environmental technology complete this portfolio.

In a total of 5 factories, more than 350 employees ensure that WAYAND operates competently and reliably for its customers across the entire market.

Die Herausforderung: Auf einen Blick

Wayand – Die Herausforderung

Wenn es um Kunststoffkomponenten wie komplette Aerodynamikkits, Front-/Heckschürzen, Seitenleisten oder um Extras – wie Sportspoiler – geht, ist die Wayand AG für viele führende Autohersteller die erste Wahl. Das Unternehmen entwickelt und fertigt seit vier Jahrzehnten Innen- und Außenbauteile in exklusiven Klein- und Mittelserien für Autos und Nutz- und Agrarfahrzeuge.

„As an automotive supplier, there is more and more pressure to keep up with our competitors. By using our SAP ® ERP solution the warehouse management is designed effectively in order to increase delivery performance significantly. At the same time, we have established streamlined storage and supply processes. Or in other words, the course for a strategic expansion of our product portfolio is set.“

An important key to success is the just-in-time delivery in Europe. Until now the manually managed central warehouse prevented a perfectly synchronized delivery of all components right into production. The first-in-first-out method could not be implemented consistently.

Wayand

Warehouse management and picking in SAP

Wayand – The Project

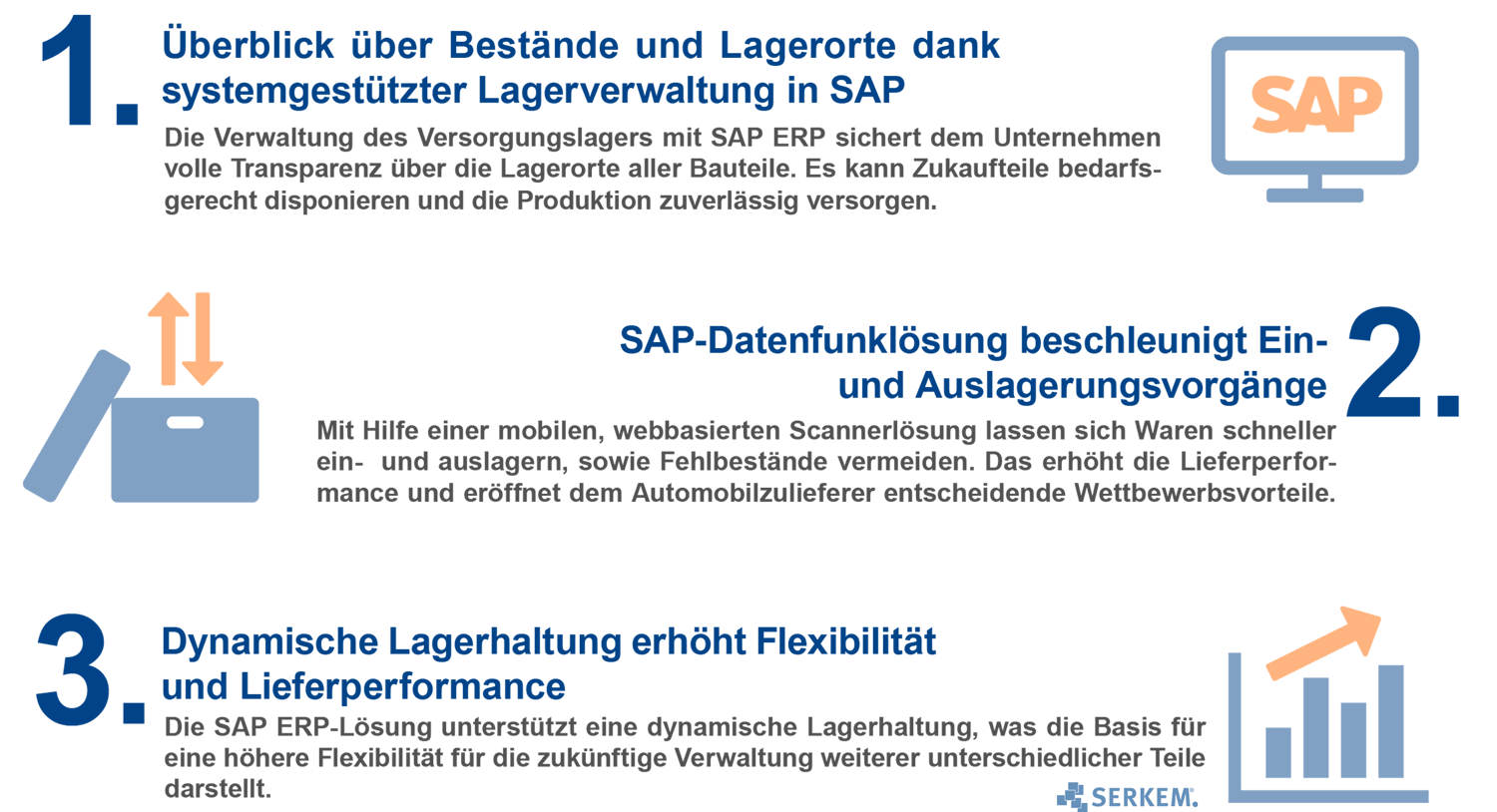

Overview of inventories and storage locations thanks to system-supported warehouse management in SAP

The Wayand AG manages its supply warehouse by using SAP ERP.

The company has an overview of resources and storage locations of components at any time. It can calculate bought-in parts as needed and provide the production steadily.

SAP data transmission solution accelerates the warehousing processes

Thanks to a mobile, web-based scanning solution quick and easy storage and removal of goods is possible and stockouts are avoided. This provides higher delivery performance and offers competitive advantages for the automotive supplier.

Dynamic warehousing to optimize the use of all storage bins and warehouse movements

In addition the SAP solution – implemented with the help of SERKEM – supports dynamic warehousing. This way the Wayand AG gains the flexibility required to efficiently manage a broader variety of on-demand parts in the future.

„Due to a more efficient warehouse management we can improve our delivery performance significantly. At the same time, we have set the course for a strategic expansion of our product portfolio”, says Brigitte Flaß-Wolf, Board Member, Wayand Inc.