Production backflush in SAP

Confirm data to the SAP system directly, worldwide and in real-time from your work place in production

The SERKEM solution in detail

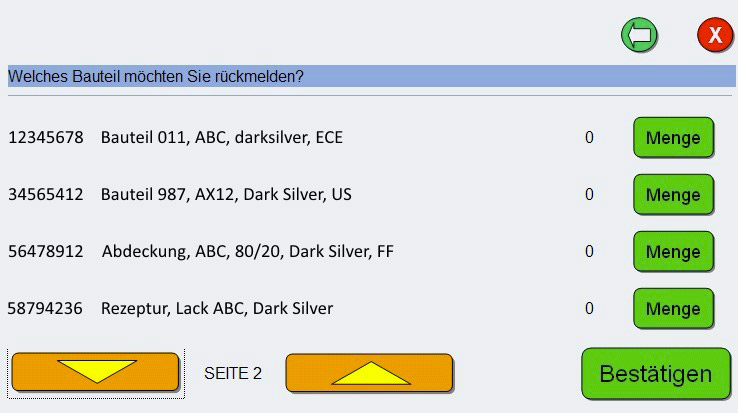

The new backflush monitor based on a webdynpro enables global feedback of good parts, rework and scrap. With the production backflush from SERKEM, the message is sent to the system in real time, directly via mobile devices from the workplace in production.

At a Glance

The SERKEM webdynpro-backflush-application consists of six websites:

Scan, material selection, options, printing, input and confirmation.

The surfaces are suitable for touchscreen operation but data entry via scanner is also possible. Additionally configured input aids simplify operation for your employees in production.

- Entering the data via scanner or touch control, input aids (e.g. material groups) can also be configured

- Confirmation or material number possible as entry

- Simple customizing

- Print receipts and labels

- Posting the confirmation with integration in the SAP standard (confirmation, data master, etc.)

- Error log is output in the event of errors

The solution for production backflush offers the possibility to transmit the confirmation directly from the workplace in production worldwide and in real time to the SAP system.

The feedback on different production levels is independent of platform and SAP GUI. The process can be parameterized via feedback scenarios and can be controlled differently in the flow logic.

- Individualized screen sequences

- Easier operation with input help

- Confirmation data are immediately visible in the system

- The surfaces are suitable for touchscreen operation

- The confirmation directly from the workplace in production

- Worldwide data transmission to the SAP system via the web address

- Worldwide real-time feedback through the web address

- The backflush monitor can be displayed on any mobile device

- Based on the scenario concept, different screen sequences are possible for different feedback levels

- Permissions and printers can be assigned to the terminals

- Only required information is displayed, operation is made easier

- User control takes place via a fixed user per terminal

- Continuous login, the session is retained (no new registration required)

Extract from our References

Wayand AG

- Automotive industry

- Turnover: 51 Mio. € (2013)

- Employees 355 (2013)

ZF Friedrichshafen AG

- Automotive industry

- Turnover: 16,8 Mrd. €

- Employees 72.600

BK Giulini GmbH

- Chemical/pharmaceutical

- Turnover: 472 Mio. €

- Employees 966 (2014)