Results of the Project

“We have achieved our project goals 100% and plan to implement SERKEM’s freight cost monitor at additional locations in the future. Since the solution was fully implemented in SAP, there are no additional licensing costs. And due to the open, transparent program structures, we can largely carry out the rollouts independently from TRUMPF.”

Christian Füssel, Project manager, TRUMPF GmbH & Co. KG

TRUMPF

The whole story

TRUMPF – The Costumer

As an independent family business the high-technology company TRUMPF provides manufacturing solutions in the fields of machine tools, lasers and electronics.

These divisions are centrally organized by the management holding company of the TRUMPF GmbH + Co. KG. A global network of comprehensive production, sales and service companies supports the holding.

In the global delivery of its products, TRUMPF relies on various logistic service providers. Moreover, besides quality and excellent products, highly efficient processes are one of the main priorities of the internationally operating high-technology company.

Die Herausforderung: Auf einen Blick

TRUMPF – The Challenge

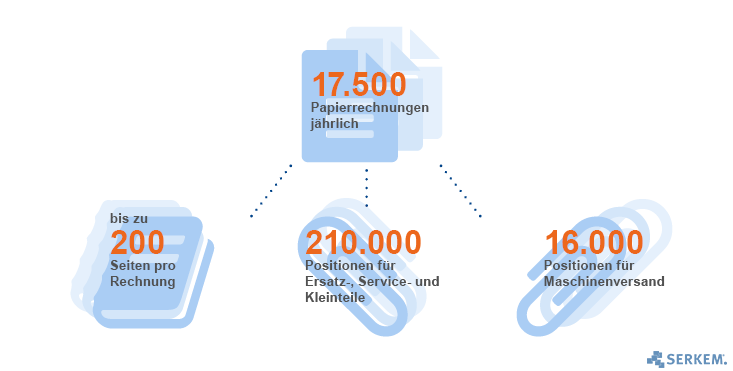

About 17,500 paper invoices from logistic service providers are incurring every year in Ditzingen for conducted freights. They include 210,000 posts for replacement parts, service parts and spare parts as well as 16,000 posts for machine shipping.

TRUMPF handles 90% of all freights with 5 logistic service providers, with which certain terms have been agreed.

After receiving the invoices from the service providers, TRMUPF has to check them for deviations from the agreed conditions. An enormous effort, as the invoices comprise partially up to 200 pages. Altogether, the manual audit of the freight expense reports is a time-consuming and error-prone process.

When TRUMPF receives the invoices from the service providers, they must be checked for deviations from the agreed terms. This is an enormous effort, as the invoices can sometimes comprise up to 200 pages. Overall, the manual verification of freight cost settlements is a time-consuming and error-prone process.

„Due to the strong growth in the volume of shipment, it was foreseeable that an examination of the invoices in the future could only take place on a random basis. The recognition of incorrect statements would be by chance. The manual audit was neither audit proof nor complied with the requirements of a genuine control of the service provider.“

Therefore it was the objective at TRUMPF to simplify the process considerably and to reach a significantly higher test quality.

TRUMPF

Automated electronic shipment cost processing in SAP

TRUMPF – The Project

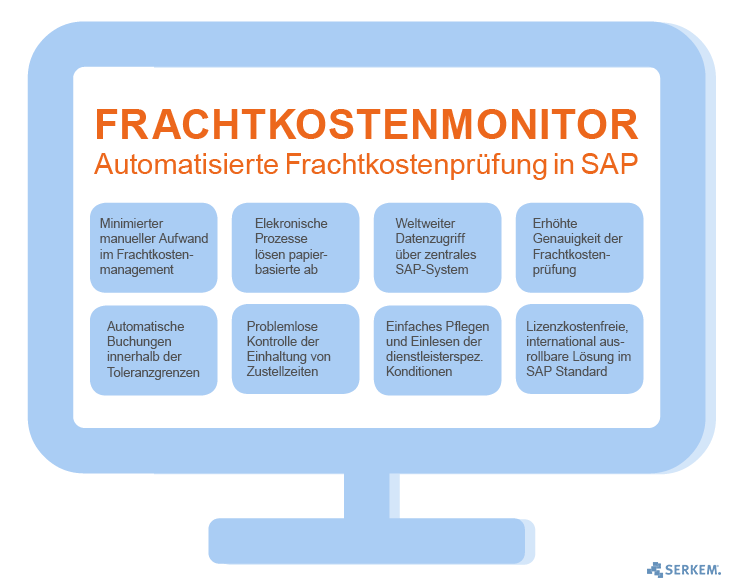

The purchasing, shipping and IT department of TRUMPF decided to automate the processing of incoming invoices from logistic service providers in order to maximize the accuracy of the freight cost check and to minimize the manual effort. The electronic incoming invoices from the service providers should be checked automatically and booked by the system if they stay within a defined tolerance range. Positions with values outside of the threshold value should be marked and manually checked in the following step by the shipping department. At the same time, the new solution should be user-friendly for staff and international roll-outs should be possible without much effort, too.

During the subsequent tender, the SERKEM GmbH convinced with a directly implemented freight cost solution in SAP. All requirements from TRUMPF are implemented user-friendly in SAP. A freight-cost-monitor – the core element of the solution – enables monitoring and clear control of all operations.

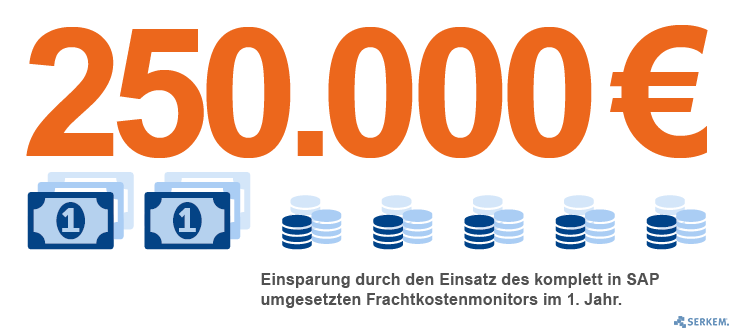

Savings of more than € 250.000 in the first year

TRUMPF saved 250,000 € thanks to the use of the SAP-based freight cost monitor in the first year . At the same time, the SERKEM-monitor serves as a tool to evaluate the delivery reliability of the service provider more efficiently.

And even the services providers of TRUMPF benefit from the SERKEM solution: the extensive automation shortened payment times significantly.

„We have reached our project goals by 100% and plan to implement the freight cost monitor of SERKEM at other locations in the future. As the solution was fully implemented in SAP, no additional license costs incurred. And due to the open and transparent program structures, we (TRUMPF) can perform rollouts largely on our own.“

„Für uns als Dienstleister ist es wichtig, dass der Kunde mit Projektende vollständig über die Lösung verfügt und sie auch unabhängig von uns weiterentwickeln kann – schließlich möchten wir den Kunden nicht über Lizenzvereinbarungen an uns binden sondern ihn durch unsere Leistung überzeugen, neue Projekte wieder mit uns als Partner umzusetzen,“ ergänzt Projektleiter Sascha Reischl von SERKEM.