SAP Kanban

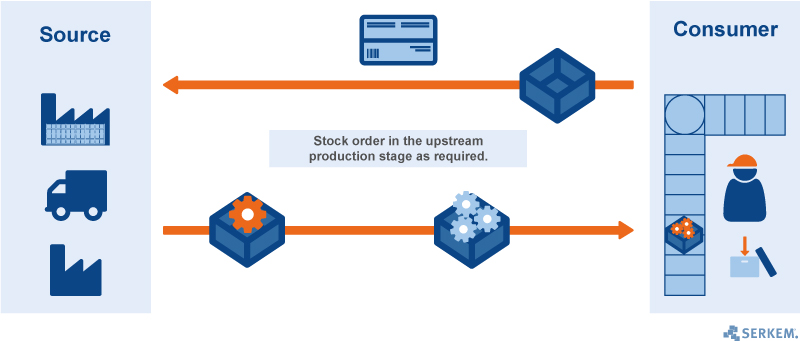

Production and material flow control in production with SAP Kanban

The SERKEM solution in detail

Due to the direct alignment of production to customer requirements and the simple mechanism for triggering requirements, inventories can be kept low on the customer and supplier side. The planning and control effort for the order processing process is minimized.

SAP Kanban

If SAP is used to support the Kanban process, system and media breaks can be reduced and the replenishment lead time of materials can be reduced by up to 50%. This is achieved by automating and merging the necessary bookings. Scanning the Kanban cards using mobile scanners can significantly reduce manual entries and thus the error rate.

SAP offers different, location-independent, controllable Kanban methods that can be used in different company areas. SERKEM has further optimized and simplified the SAP Kanban processes. This further increases the efficiency and overview in the Kanban chain.

At a glance

SERKEM offers you the expansion of Kanban processes in the SAP standard:

Extract from our References

Schleifring und Apparatebau GmbH

- Electrical engineering and transmission technologies

- Turnover: 134 Mio. € (2017)

- Employees: 650 worldwide (2017)

ZF Friedrichshafen AG

- Automotive industry

- Turnover: 16,8 Mrd. €

- Employees 72.600