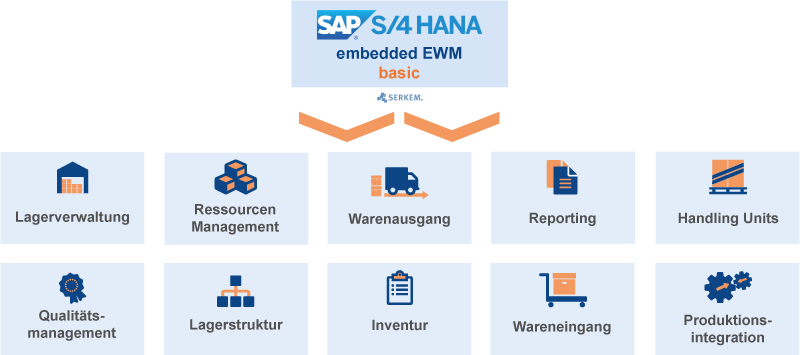

SAP S/4HANA embedded EWM basic

Warehouse Management in S/4HANA

Embedded EWM basic in detail

Extract from our references

Oettinger Davidoff AG

- Tobacco industry

- Turnover: 500 Mio. CHF (2018)

- Employees: 3.600 (2018)

AlzChem AG

- Chemicals

- Turnover: 295 Mio. €

- Employees: 1.400

AlzChem AG

- Chemicals

- Turnover: 379 Mio €

- Employees: 1.630

Continental AG

- Automotive Supplier

- Turnover: 44 Mrd. € (2017)

- Employees: 235.000 (2017)

Büroring eG

- Purchasing, marketing, and service cooperative society of office supply retailers

- Revenues: 206 million € (2012)

- Employees: 81 (2013)