SERKEM SAP EWM warehouse

control center

Transparency and an overview of all movements in the warehouse with the SAP EWM warehouse control center from SERKEM!

The SERKEM solution in detail

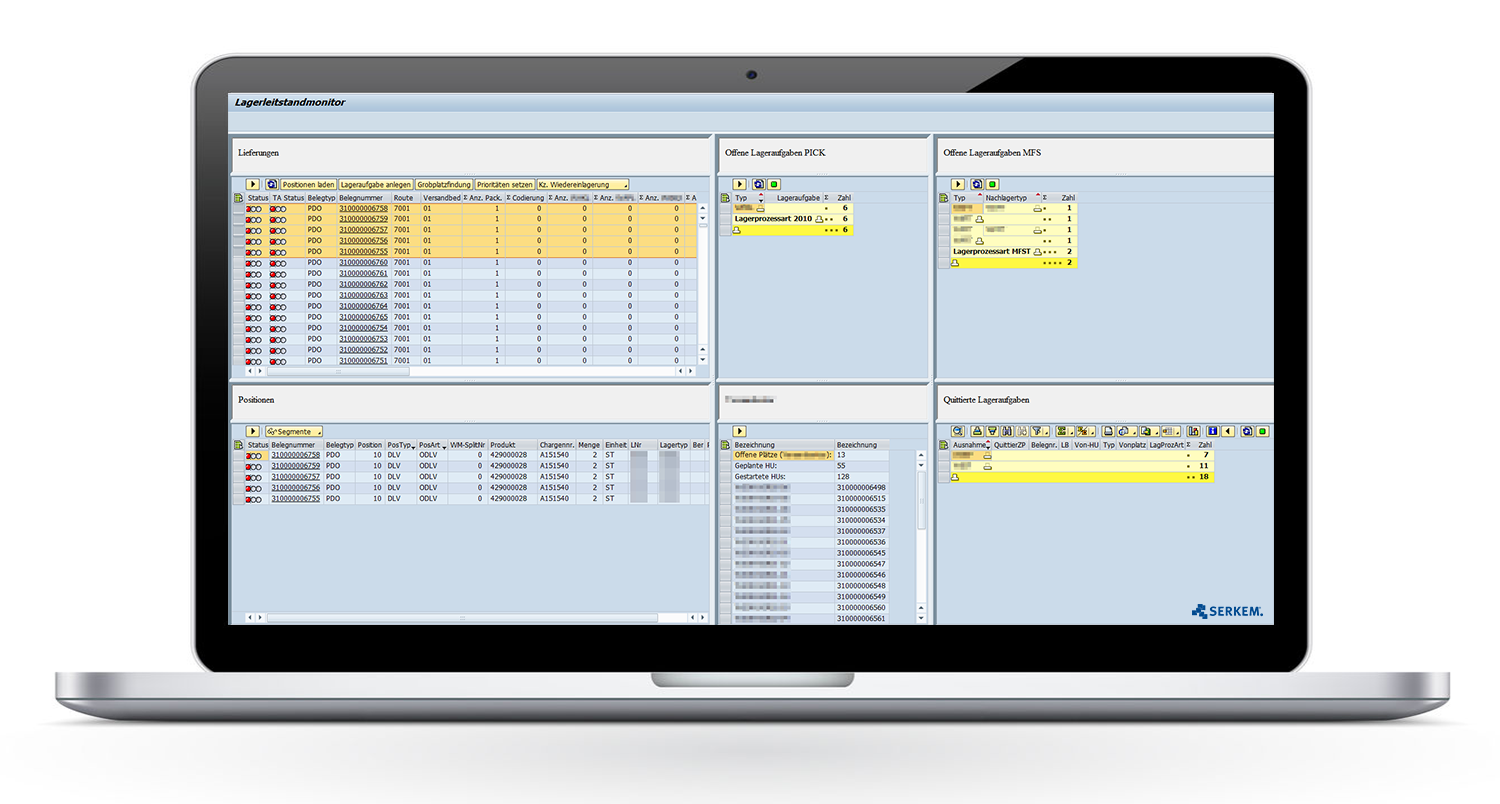

SERKEM SAP EWM warehouse control center

The SERKEM control station provides a complete overview of all key areas in your SAP EWM system and can be added as a template to your SAP EWM system. The control station covers the following basic functions, among others:

Selection screen

Selection screen of the SERKEM SAP EWM warehouse control center

First, a selection screen appears with multiple tabs. You can differentiate between deliveries, multiple open warehouse tasks, and confirmed warehouse tasks. The following selection criteria can be chosen for each respective tab.

Individual areas in detail

Areas of the SERKEM SAP EWM warehouse control center

Complete overview

Extract from our References

SEW-EURODRIVE

- Automation

- Turnover: 2,7 Mrd. € (2015/16)

- Employees: 16000 worldwide (2016)

AlzChem AG

- Chemistry

- Turnover: 295 Mio. €

- Employees: 1.400

AGCO

- Agricultural machinery

- Turnover: 9,96 Mrd. $ (2012)

- Employees: 20.320 (2012)

Further Information

Downloads

Arrange a live-demo

Here, you can register for your free and non-binding live demo. Schedule a session now, and our experts will demonstrate all the features live on the SAP EWM system.