Results of the Project

„Before the project, various CEP (courier, express, and parcel) service providers at SEW-Eurodrive were integrated into the shipping processes in different ways. The goal of the project was to establish a standardized and rollout-ready integration of the CEP service providers.“

Armin Neff, Team Leader, IT-Services Production & Purchasing

SEW EURODRIVE

The Whole Story

SEW-EURODRIVE – The Customer

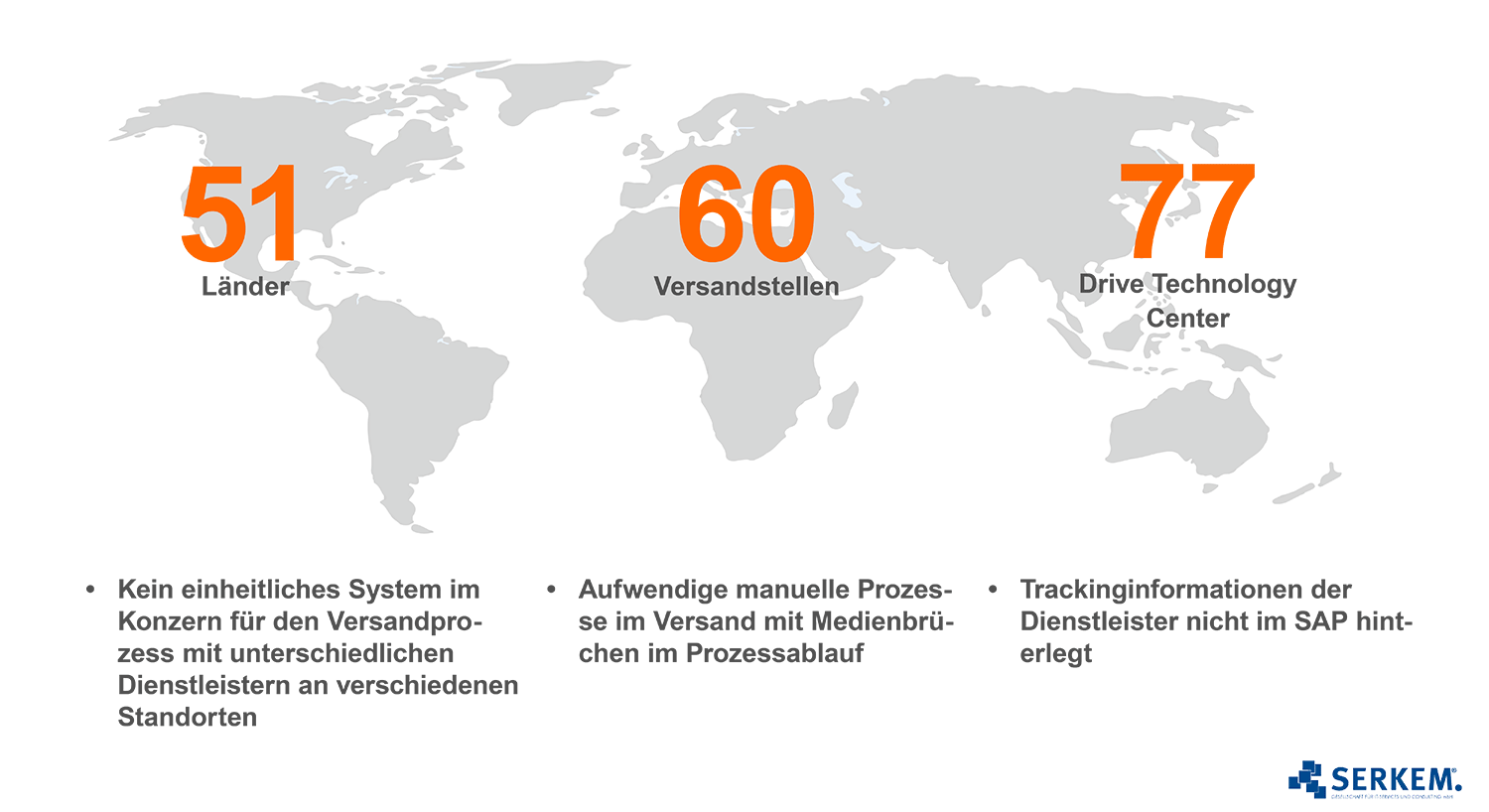

SEW-EURODRIVE is a German global acting company group which is represented in over 50 countries with production-, assembly plants and sales branches.

Dependent on requirement or industry, SEW-EURODRIVE offers individual solutions from a comprehensive kit of gear engines and frequency converters, servo drive systems, decentral drive systems and industrial gears. SEW-EURODRIVE is technology- and market leader in the area of drive technology/drive automation. In addition, SEW-EURODRIVE offers scalable application solutions (Variolution-Packets) and individual system solutions (Maxolution).

In the assembly plants in Germany, France, China and Finland the components are produced in advance. The end products are assembled in 75 installation factories worldwide and tailored to the customers´ needs.

The Challenge: At A Glance

SEW EURODRIVE

Connecting 3 countries and

5 Service Providers in 6 months

SEW EURODRIVE– The Project

„Before the project the various CEP service providers were integrated at SEW-Eurodrive in different ways. Target of the project was to establish a standardized and rollout able solution for connecting the CEP service providers.“

SEW-EURODRIVE is very satisfied with the solution and the project success:

„The previous projects with SERKEM could be carried out very pragmatic and cooperative in a short time. It is planned to roll out the flexible solution gradually in the whole SEW group, as needs arise.“

Image material: © SEW-EURODRIVE GmbH & Co KG