Results of the project

RUAG

The whole story

RUAG – The Customer

RUAG, an international technology group for Aerospace (Aerospace) and Defence (security and defense technology), maintains production sites in Switzerland, Germany, Sweden, Austria, Hungary, Australia and USA.

Today more than half of RUAG’s net sales are generated outside the Swiss domestic market. The basis for the global success are innovative, high quality products and services.

The group is divided into five divisions: Space, Aviation, Aerostructures, Ammotec and Defence.

The Challenge: At a glance

RUAG – The Challenge

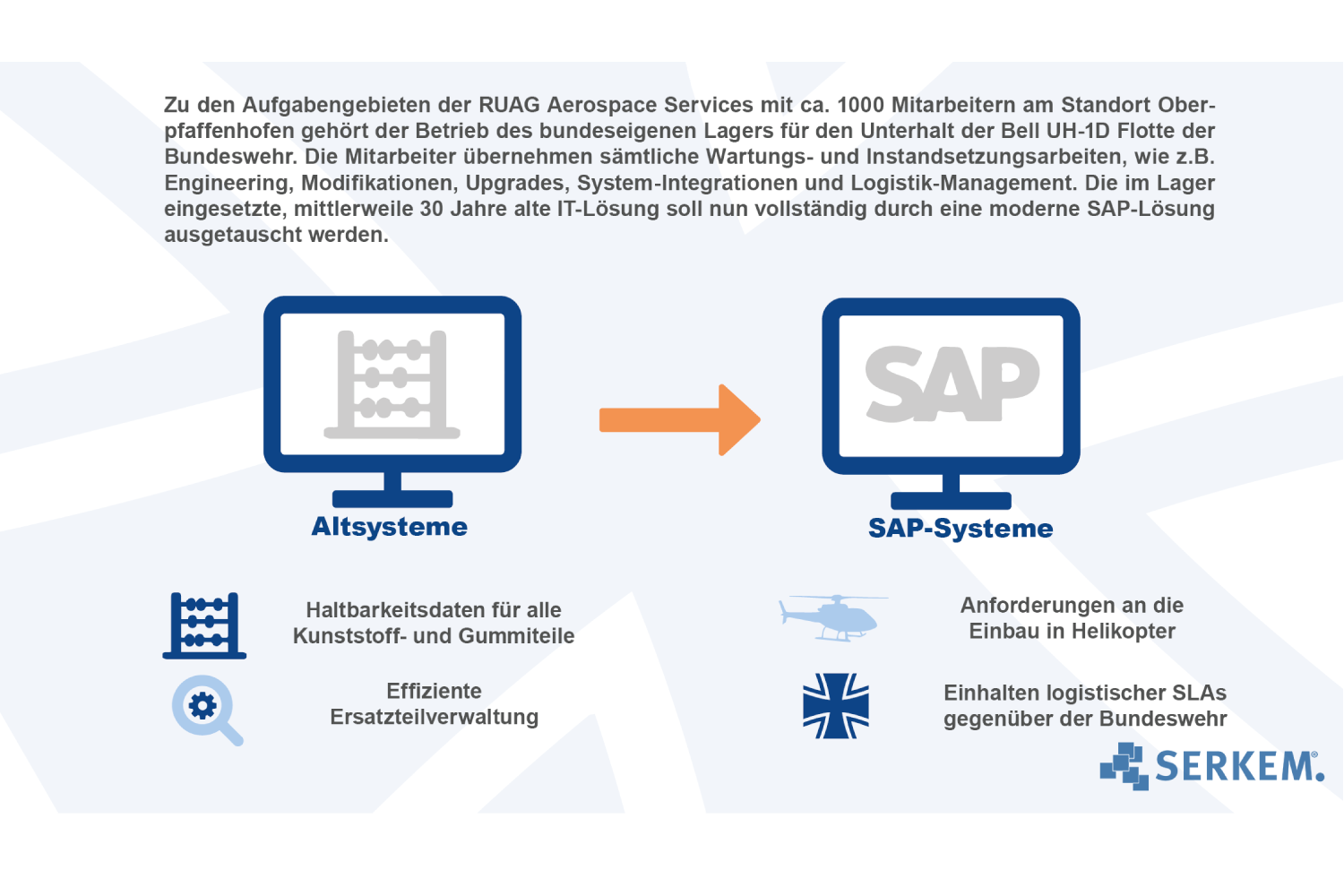

One of the tasks of the RUAG Aerospace Services is the operation of the federally owned warehouse in Oberpfaffenhofen. The approximately 1,000 employees at the site are responsible for the upkeep of the Bell UH-1D fleet of the German Bundeswehr and take over all maintenance and repair work as well as engineering, modifications, upgrades, system integration and logistics management.

Until now ,the IT solution, developed over 30 years ago, was only modified step by step. The functional areas must be adapted to regulations of the ÖAG.

In order to provide long-term security for this business, the RUAG Group is planning the migration of the IT Module “BEL” in the existing RUAG standard SAP environment.

In addition to time pressure, other challenges are specific requirements for durability acquisition, spare parts management, installation in helicopters, etc. that need to be mapped and considered in SAP.

RUAG

System-Migration in 8 months

RUAG – The Project

100% SAP-Standard

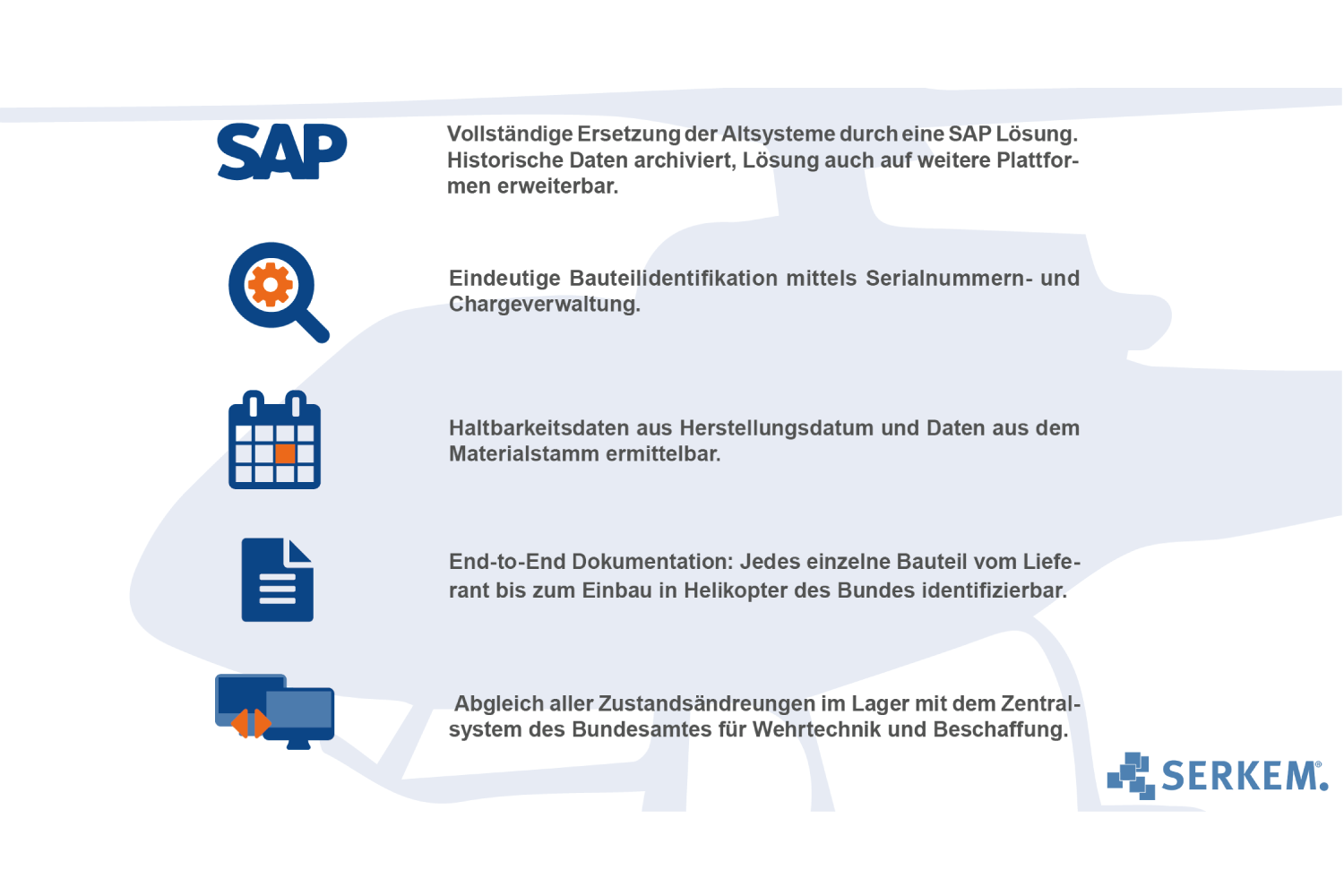

With the help of SERKEM, migration took place in less than 8 months. All the necessary add-ons were implemented in the defined SAP name space and are therefore encapsulated.

The existing systems in BEL were completely removed and replaced by a SAP solution. For RUAG that means, that all processes are now mapped in SAP, based on standard objects.

100% covering requirements of the operator

The special demands on the spare parts warehouse, operated by RUAG, are also taken into account in the SAP system.

The SAP solution by SERKEM ensures that all components can be identified clearly, that there is stability data for all plastic and rubber parts and that documentation includes all stations. There is compliance with logistical SLAs on part of the federal government and all other departments and maintenance of machinery is being met.

For unique component identification serial numbers and batch management is being used. Serial numbers label each product, therefore they can be distinguished from one another. Depending on the used material, stability data for all plastic and rubber parts is added. It is generated by the SAP system using the date of production and stability data from the Material Master Data.

100% traceability and documentation

The SAP solution implemented by SERKEM provides RUAG an end-to-end documentation. This means that all stations of a component can accurately be tracked and assigned – from the supplier to the installation in a federal helicopter.

In the daily data exchange, all movements and changes of state in the warehouse are compared with the central system of the Federal Office of Defense Technology and Procurement. Therefore, the central systems always has up-to-date data from the federally owned warehouse in Oberpfaffenhofen.