Goods Receipt in SAP EWM

Optimized goods receipt and belonging processes in SAP EWM

Your Requirements

- Mapping of complex processes in SAP EWM

- Efficient and effective processes for incoming goods

- Integration of ERP and EWM

- Goods receipt control

Our Solution

- Conception of optimized goods receipt processes

- Template concept with predefined templates

- Creation of deliveries and further processing to EWM

- Integrated storing in automated warehouse

Your Benefits

- Fast realizability

- Flexible customizing

- Efficient and cost saving processes

- Easy adaptability

The SERKEM solution in detail

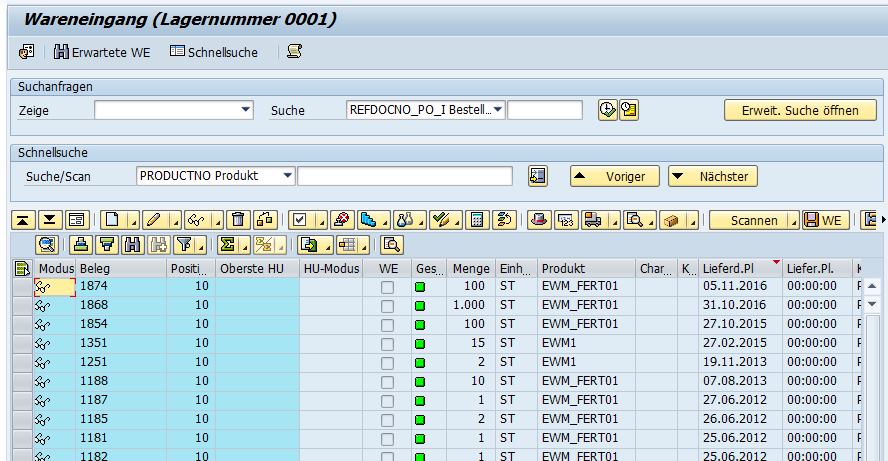

Goods receipt in SAP EWM

In the goods receipt process, both the ERP system and the EWM system are involved. Communication begins with the creation of an inbound delivery in the ERP system, which is then forwarded to the EWM system. The inbound delivery created in the ERP system is set up in the EWM system based on attributes such as batch, production date, pallet, or container. Additional attributes can be transferred from the ERP system.

In the goods receipt process, the management of arriving trucks is also carried out. The gate control directs incoming trucks to a goods receipt gate either manually or automatically.

Automatic validation of delivery notifications

The automatic validation of delivery notifications is an add-on to SAP WM and takes place at the base on automatic incompleteness and consistency controls.

Therefore the data quality for further processes in the goods receipt area is guaranteed: the delivery positions with errors are blocked for further processing until they will be corrected.

The registration can be made either paper based or with mobile data collection. Every material is registered with scanner. Through the integration in SAP the actual inventory is always available in real time.

Registration of goods receipt parts for new documents and correction posting

If delivery positions are missing, SAP EWM makes it possible to split or delete the delivery positions. For the open amount or missing delivery positions a new delivery will be created.

If suppliers are not able to send notifications of delivery dates, new documents, which are developed at the base of order information and transactions, accelerate the system-sided registration of delivery dates.

Additionally the correction postings can be booked in SAP EWM during the whole putaway process. The booked goods receipt amount will be customized. This is an advantage especially at relocation sceneries.

Deconsolidation as a new function in SAP EWM

For delivered mix-container SAP EWM notices automatically if the content has to be deconsolidated. SAP EWM can identify automatically the deconsolidation station as well as create the necessary transport in the form of a storage task.

The goods receipt process will be accelerated.

Quality control integrated in EWM

SAP EWM identifies automatically if the delivered goods have to be quality controlled. The system executes automatic test station detection. Follow-up activities can be flexibly defined. Depending on the test result, the defined logistical follow-up activities are initiated automatically.

Beside the integration of EWM in the Quality Inspection Engine (QIE) an additional interface in ERP QM exists. Extensions of this integration are released with EWM 9.1. Then it is possible to control partial quantities.

Storage disposition and storage reorganization directly in EWM

SAP EWM identifies the optimized storage bin at the storage dispositon per product-, requirement- and packaging dates.

The storage reorganization optimizes the structure of products in the warehouse at the base of storage disposition dates.

In combination with the storage reorganization, the storage disposition takes care that the right product is with the right amount at the right storage bin. This establishes a basis for a way-optimized picking.

Beside the more effective picking processes, this combination involves a maximizing of warehouse capacity as well as minimizing of replenishment processes.

The warehousing process is primary the shipment from goods receipt zone to the storages (manual storages as well as dangerous goods storages, cold storages, special storages, disposal storages, etc). For example, a pallet can be physically put on the container conveyor technology.

The pallets and handling units can be system-sided creates for special working places. Different scan processes can organize the warehousing more efficient and more effective. During the warehousing process, conformity checks can be executed – for saving the quality.

In the EWM system there is the choice between different criteria of goods at the warehousing process. For example, it can be differentiated between temperature, dangerous goods, pallet size etc…

If there is a suitable alley, the warehousing in the automated pallets storage can be executed. At first, a storage area will be chosen. The selection of the correct storage area takes place especially through the EWM system.

The conveyor technology maneuvers the handling unit in the relevant storage area. The communication between the container conveyor technology, the automated pallet storage and the EWM system takes place through standard telegrams. Reporting points in the EWM system are defined, which presents relevant reporting points at PLC level (light gate, sensors, etc). Further, the acknowledgement, confirmation and error messages are also mediated over telegrams to the EWM system.

Improved stock order creation in SAP EWM

The stock order creation in SAP EWM provides the creation of optimized working packages for resources in the warehouse.

Storage tasks can be bounded in the relevant order at the base on a flexible set of rules for:

- optimization of way times

- picking of heavy products ahead of light products

- consideration of maximal weight from stock order

The needed picking containers can be calculated and automatically created.

Optimization of storage control

With the new function for storage control in SAP EWM, complex warehousing processes as well as storage-internal processes can be flexibly defined and controlled. All happens in consideration of the storage layout.

SAP EWM calculates automatically the next process step and can automatically create the relevant storage task.

The automated control of storage processes reduces the process duration significant: Goods are stored faster and are available earlier for further distribution.

Extension through better integration

Through the storage control in EWM, the process of logistical extrea services is better integrated in goods issue and goods receipt.

Additionally, necessary supporting products can be inventory-managed.

SAP WM – SAP EWM: Extension with new objects

Better integration of yard processes in storage processes through new objects:

- transportation unit for container

- storage gate

At the arrival of trucks on control points, the registered stocks in the warehouse are already visible. The prioritization of unloading can be carried out.

The resulting reduction of downtimes increases the efficiency in the yard. These can be further increased with integration of a yard management system.

Extension with additional possibilities

In WM the transport cross docking (TCD) process is started manually.

In EWM the TCD and goods distribution were supported as a planned cross docking scenario.

The TCD process works at the base of route planning, so the cross docking relevance is fixed before the income of goods.

Only EWM knows the following functions for minimizing the delivery delay:

- Picks from Goods Receipt, PFGR

- Push Deployment (PD) as unplanned CD scenario

- Opportunistical CD scenarios

SAP APO determines in EWM the cross docking relevance at the base of backward customer orders with cross docking variants: the goods are delivered immediately after the goods receipt either to the customer (PFGE) or in another warehouse (PD).

The PFGR variant is not supported for customer orders from the SD module.

SAP WM – SAP EWM: Integrated customs clearance as a new function

The combination of EWM and GTS makes the integration of customs processes in the storage activities possible.

The following controls are possible bevor unloading and loading of the truck within the shipping process

- Is there an unloading and loading permission from the customs?

- Is a delivery to a specific goods recipient possible?

Additionally, SAP EWM supports the temporary deposit and the customs warehousing procedure.

Extract from our references

SEW-EURODRIVE GmbH & Co KG

- Manufacturing industry

- Turnover: 2,7 Mrd. € (2015/16)

- Employee: 16000 worldwide (2016)

AlzChem AG

- Chemicals

- Turnover: 295 Mio. €

- Employees: 1.400